Are you a factory?

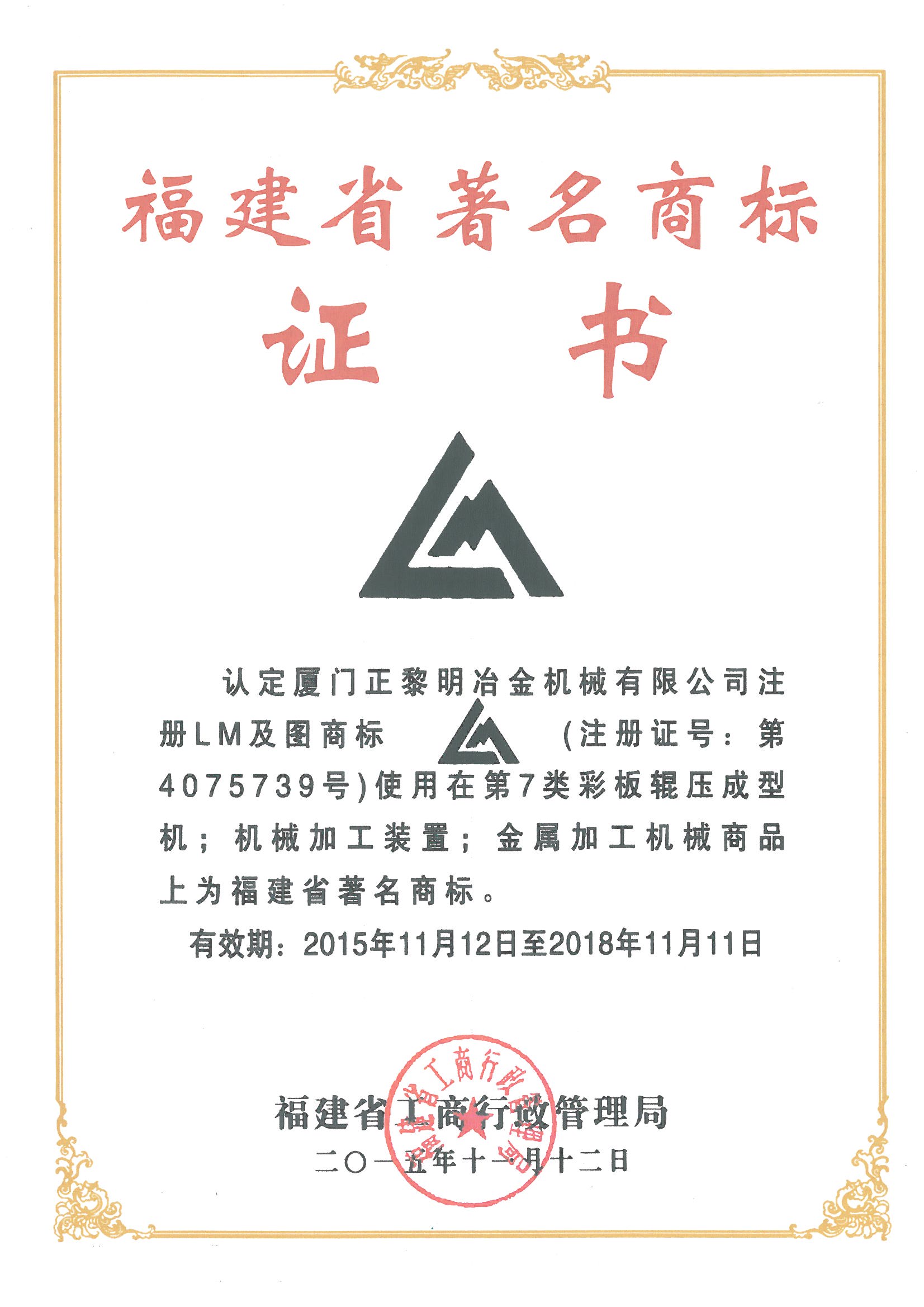

Yes, we are a factory. Xiamen Zheng Liming Metallurgical Machinery Co., Ltd, founded in 1989, has been in business for more than 30 years and covers an area of more than 100,000 square meters. It is the first manufacturer specializing in the manufacturing industry of various cold rolling mills/ roll forming lines in China.

How about the strength of your factory?

Our factory was founded in Xiamen in 1989, covering an area of more than 100,000 square meters. We are a national high-tech enterprise, a national standard maker, a municipal-level enterprise technology center, with 18 invention patents, 77 utility model patents and 1 appearance design patent.

Do you have after-sales support?

We will provide technical support for the whole life cycle of the machine. And we also have skilled technicians available on hand. If you need, we can send our technicians to train your staff.

How do you guarantee that you can make the machine as order?

We have industry-leading technicians, professional teams. We focus on the combination of production, R&D, and studying. We also cooperate with universities and specialize in difficult and feasible solutions for the industry. We have nearly 100 R&D people and production staff to produce light– structured and reasonably designed machines in time to meet our customers’ needs.

How does your factory do regarding quality control?

Quality is priority. First of all, we have in-house laboratory and scientific quality control department. Secondly, we have 146 sets of high-end professional production equipments, multiple process quality inspection to ensure product quality. Most importantly, Zheng Liming always attach great importance to quality control from the very beginning to the end of the entire production. Every roll forming machine will be fully assembled and carefully tested before it’s packed for shipment.

Do you sell only standard machines?

No, most of our roll forming machines are built according to customers specifications, using top brand components.

一种异形截面板无极角度翻转堆叠设备_页面_1-scaled.jpg)